ESP8266 - Motor

This tutorial instructs you how to use ESP8266 and motor. In detail:

- The types of motors that can be used with ESP8266

- The distinctions between the different types of motors

- How to manage each type of motor

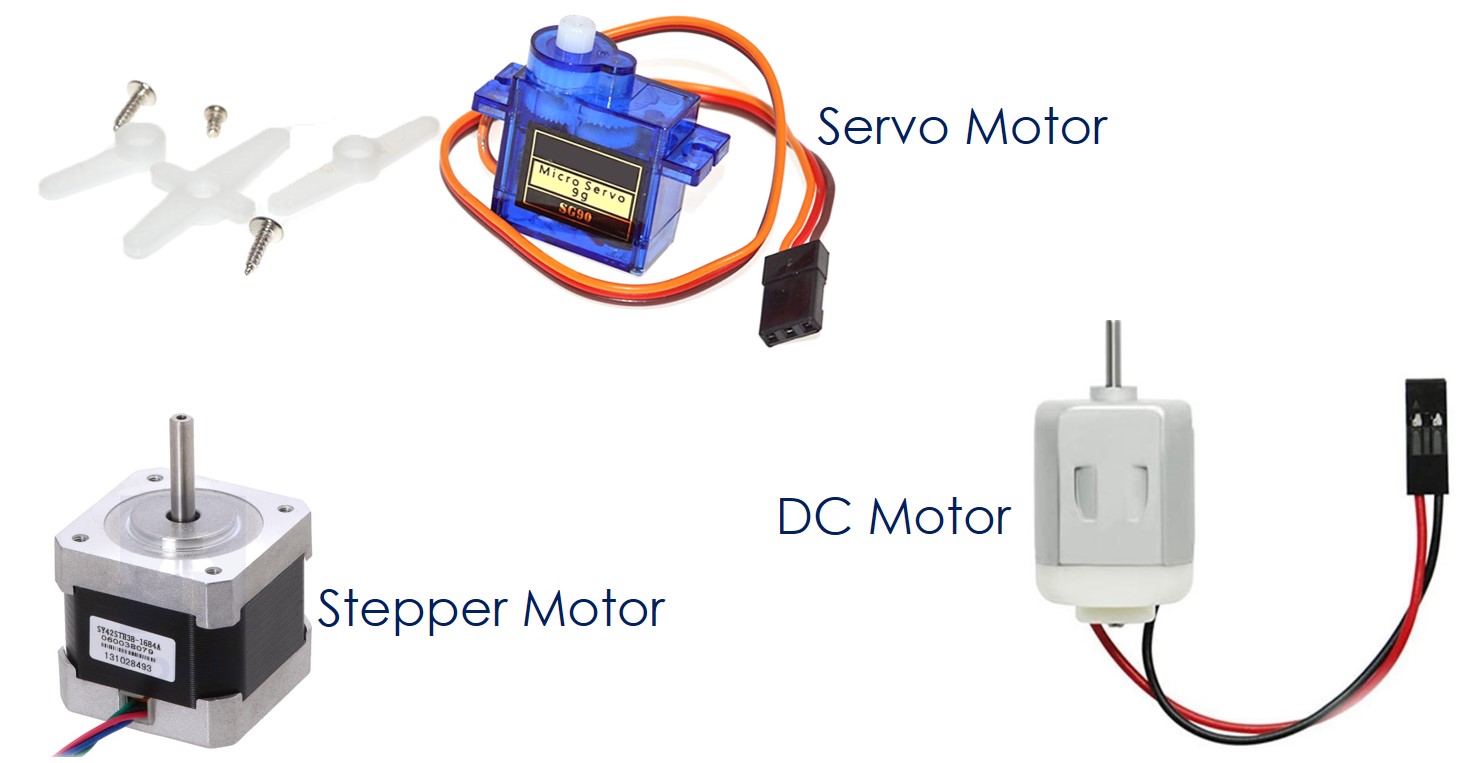

Motor Types

There are three sorts of motors that are frequently used with Arduino:

- Servo motor

- Stepper motor

- DC motor

There are two distinct varieties of servo motor: 180° servo motor and 360° servo motor. Generally, when people think of a servo motor, they are usually referring to the 180° type.

A 360° servo motor is comparable to a DC motor, however, it does not require a hardware driver.

180° Servo motor

Characteristics

- The range of rotation is between 0° and 180°.

- It can be rotated in both clockwise and counter-clockwise directions.

- The position of rotation can be adjusted to a particular angle between 0° and 180°.

- The speed of rotation can be regulated, but not in a smooth manner.

- No extra hardware driver is needed for control, just an ESP8266 pin.

- An additional power source is required.

- Controlling it is straightforward, just use a PWM signal.

Application

- Can be done using a single servo motor

- Any application which necessitates the rotation of an angle between 0° and 180° can be accomplished with a single servo motor.

Servo motor Tutorial

Check out our ESP8266 - Servo Motor tutorial for more information.

Stepper motor

Characteristics

- Provided

- The amount of rotation is not limited.

- The direction of rotation can be clockwise or counter-clockwise.

- The position of rotation can be precisely adjusted to any angle.

- The speed of rotation can be precisely controlled, as well as the acceleration and deacceleration.

- Additional hardware and power supply are necessary.

- Controlling the rotation is complex, so those new to it should use the library provided.

Application

- Automation and robotics

- Printers, 3D printers, CNCs, X-Y plotters

- Cocktail Machines

Stepper Motor Tutorial

- ESP8266 - Stepper Motor tutorial

- ESP8266 - 28BYJ-48 Stepper Motor tutorial

DC motor

Characteristics

- The amount of rotation is not limited.

- The direction of rotation can be either clockwise or counter-clockwise.

- It is very difficult to rotate to a specific angle with precision.

- It is easy to control the speed, but it is hard to precisely control it to a certain value.

- A hardware driver is necessary.

- An extra power supply is also needed.

- Controlling it is simple, just use a high-voltage PWM signal.

※ NOTE THAT:

- , which makes it easier to control the position of the motor.

- To regulate the position of a DC motor, additional hardware is required, known as an encoder, and a closed-loop control method such as PID control must be implemented. This can be challenging for those who are new to the process.

- Speed control is much simpler, with options such as slow, medium, fast, and very fast, as well as being able to set the speed to a certain percentage of the maximum. However, to control how many revolutions per second, an encoder and a closed-loop control method such as PID control must be used. This is a difficult task for beginners.

- Fortunately, some DC motors come with an integrated encoder, making it easier to manage the position of the motor.

Application

- Previously used to manage something that requires a continual rotation, but the speed does not need to be determined. Examples include fans, pumps, RC cars, drills, etc.

※ NOTE THAT:

There are two primary types of DC motors: brushed and brushless. Brushed DC motors are commonly used in DIY projects.

DC motor Tutorial

Check out this tutorial on ESP8266 - DC Motor! . Learn how to use an ESP8266 to control a DC motor.

Motor selection guide

When selecting a motor for a project, there are many factors to consider, such as the weight it needs to carry, power supply, and the characteristics of the application:

- If your project requires rotation between 0° and 180°, look for an appropriate 180° servo motor.

- If your project requires precise rotation to any position, a stepper motor is the best option.

- If your project requires continuous rotation without any specific position, a DC motor or 360° servo motor is the ideal choice.

Buy Motor

Additionally, some of these links are for products from our own brand, DIYables .